In the procurement and development of components and raw materials (hereunder materials), it is an important point in manufacturing whether to use self sourced or customer supplied materials. What are self source and customer supply? What is the difference from centralized purchasing? How do you decide whether to self source or customer supply? There are many points that are difficult to understand and available on the internet. In this article, the author, who has 13 years of experience in the procurement of metal parts, motors, and lithium-ion batteries for Toyota Motor Corporation and startup companies, will introduce the following information with his own experiences.

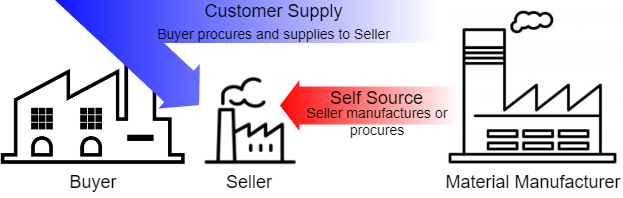

Self Source means that supplier (seller) procures or manufactures materials and parts in-house. Customer Supply means that the customer (buyer) procures and suppliers materials and parts.

The terms “Self Source” and “Customer Supply” may vary slightly from company to company and industry to industry. The relevant terms are summarized here. To clarify the relationship between customers, your company, and suppliers, the terms “seller” and “buyer” are used. Ratings such as “〇 (positive)”, “x (negative)”, “△ (neutral)” are included from the buyer’s perspective. For simplicity, hereunder, we call “material” for both raw materials and parts.

| Term | Self Source | Administrated Self Source | Customer Supply | Resale |

|---|---|---|---|---|

| Type | Self Source | Self Source | Customer Supply | Customer Supply |

| Definition | Seller manufactures in house or procures material | Seller(s) procure material with the price decided by Buyer who negotiated on behalf of Seller(s) | Buyer procures material and supplies it to Seller without selling them. Seller does not need to pay for the supplied material | Buyer procures material, supplies it to Seller, and sells it. Seller needs to pay for the supplied material |

| Material Uniqueness | ||||

| Material Quality | ||||

| Material Supply | ||||

| Fixed Cost | ||||

| Variable Cost | ||||

| Sale of Material | ||||

| Diversion to Other Sellers | ||||

| Inventory Management | ||||

| Cash Flow |

Terms other than those listed above related to Self Source and Customer Supply include,

- Centralized Purchasing

The process of grouping together materials and parts needed by multiple buyers to increase purchasing power is called centralized purchasing. The advantages are not only price, but also the stability of delivery and quality. More details will be introduced in the next section. - Company Provision

It is often confusing that “Provision” is mixed with above terms and what a company provides to its employees or contracted suppliers. To avoid confusion, in this article we define two Company Provision below as different from Self Source and Customer Supply. One is an employee-to-company case, where a company gives or lends the employee clothes (uniforms and work clothes), devices (computers and cell phones), tools (equipment, vehicles, and tools), etc. The other is a company-to-company case, in which the buying company gives or lends equipment, tools, etc. to the selling company undertaking the work for use. It is a good idea to check the definition of the term carefully and share it with others.

One method of customer supplies is centralized purchasing. Centralized purchasing means that a single buyer purchases materials and parts that are needed by multiple buyers in bulk, thereby reducing costs and stabilizing supply and quality. The seller has an incentive to discount prices because of the large volume of purchases. Seller also prioritizes the delivery, leading to stable supply. Centralized purchasing also uniforms quality of the materials and parts. As far as I know, it is practiced in the automotive, aerospace defense, and construction industries. However, there are cases in which centralized purchasing means that the head office of a company buys all the materials for its branch offices and factories in various regions. In these cases, no Customer Supply is made.

As shown in the exemplary table below, centralized purchasing is only considered as Customer Supply when the purchase is made for other companies (yellow highlights indicate Customer Supply). The greater the depth and scope of centralized purchasing, the greater the volume of purchases and the greater the potential for cost reduction. On the other hand, Customer Supply is not necessarily centralized purchasing. In some cases, as in the experience described below, Customer Supply is made even if the purchases are not made in bulk.

| Depth | Scope (Domestic) | Scope (Oversea) |

|---|---|---|

| Headquarters / head office factory | Automobile OEM | Automobile OEM |

| Branch / regional factory | Automobile OEM / Unit Assembly Factory | Automobile OEM / Unit Assembly Factory |

| Acquired branches and factories | Group automobile OEM | Group automobile OEM |

| Supplier Tier1 | Supplier of Automotive OEM | Supplier of Automotive OEM |

| Supplier Tier2 | Suppliers for Tier 1 | Suppliers for Tier 1 |

| Supplier Tier3 | Suppliers for Tier 2 | Suppliers for Tier 2 |

Centralized purchasing for yellow highlights would also be considered Customer Supply.

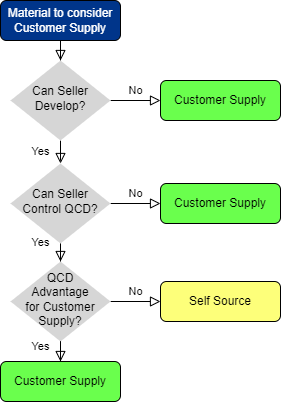

When a business-to-business (B2B) transaction starts, in most cases the seller’s components are assumed to be Self Source. To switch from Self Source to Customer Supply, the following six points are to be considered, from the buyer’s perspective.

The first point to consider Customer Supply is “Necessity” and then “QCD (Quality, Cost, and Delivery) benefits”.

Necessity means that there are cases in which the seller cannot guarantee the quality in design and manufacturing if the target material. The material may be developed by the buyer or Seller does not know much about the material. In such cases, the buyer has no choice but to arrange Customer Supply.

As another necessity, there are cases where Customer Supply is considered because Seller has difficulty in managing QCD. For example, there are cases where steel mills do not give priority to the amount of steel purchased by the seller, resulting in delays in delivery. This is also a case where the seller requests for Customer Supply.

Lastly, if there is a QCD benefit for Customer Supply, the buyer may propose or make Customer Supply as a prerequisite for businesses. For example, in Japan’s aerospace and defense industry, materials such as aluminum and stainless steel are Customer Supplied because they are specified in standards and it is more cost-effective and quality-controllable to purchase them in bulk rather than separately from each seller.

There is a tradeoff between cost and quality when considering Customer Supply.

When switching from Self Source to Customer Supply, the seller becomes free from controlling costs and quality of the Customer Supplied material. This is naturally reflected in the price. Margins (commissions) on Customer Supplied materials are reduced. If materials are Customer Supplied through centralized purchasing, the cost of parts and materials can be further reduced.

However, in the event of a defect, it may be difficult to determine whether the defect was caused by the Customer Supplied materials or by the seller, so there is a tradeoff.

If the buyer has the capability and human resources to analyze the cause of defects, switching to Customer Supply is a controllable risk. Buyer can clarify responsibility in the event of quality problems.

In considering Customer Supply, you can also consider whether to group materials together on regional or global basis. If Customer Supply is made on a global basis, it is possible to reduce costs and ensure uniform quality by increasing purchase volume. However, the more materials are grouped together, the higher the risk of quality and stable supply. Below are the advantages and disadvantages of regional and global customer supplies.

| Category | Regional Customer Supply | Global Customer Supply |

|---|---|---|

| Cost | ||

| Quality | ||

| Supply Stability | ||

| Development Time and Cost | ||

| Example |

In promoting Customer Supply, there must be an agreement between the seller and buyer. There are various cases where there are advantages of Customer Supply for the seller, or where the seller has no choice but to accept Customer Supply. Below are some points to be verified when reaching an agreement.

- Agreement on Customer Supply

Buyer explains the need or benefit to the seller about Customer Supply and reaches an agreement with the seller. The benefits can be found in the table above. - Quality

Buyer is responsible for the quality of Customer Supplied materials. Buyer and Seller will consider how to guarantee the quality of Customer Supplied materials. For example, Buyer and Seller will consider whether and how to inspect Customer Supplied materials prior to shipping or / and after receiving. - Customer Supply System

One challenging aspect of Customer Supply is inventory management. Buyer places orders for Customer Supplied materials, but the seller needs to process and deliver without delay or shortage of supplied material. Buyer and Seller will consider what kind of supply system (rules, tools etc.) to set up in order to supply the required number of materials at the timing required by the seller. - Administrative Cost

Even Customer Supply, there will be administrative tasks such as receiving inspections, inventory management, stocktaking, ordering procedures, and so on. Buyer and Seller will consider how to cover the administrative costs for these tasks. Generally, the order of administrative cost is Self Source > Administrative Self Source > Resale > Customer Supply.

If Customer Supply is NOT conducted, materials would be Self Sourced. For sellers, strengthening Self Sourced materials means using their own resources and building a sustainable business. For buyers, it is also beneficial in terms of QCD (quality, cost, and stable supply) to strengthen Self Sourced materials. Specifically, the following methods can be considered.

- Resource Audit

Seller organizes its resources, including human resources, equipment, technology, and know-how. In particular, Seller works on articulating the seller’s areas of expertise and strengths. - In-house vs Outsourcing

Seller considers whether there are any materials that can be manufactured in-house or outsourced to increase competitiveness (in terms of price or technical advantage). For example, Olympus has developed medical wires, which are difficult to manufacture, sometimes jointly with Terumo, and other times outsourced to Asahi Intec. - Productivity Improvement

Cost reductions and increased production volume can be achieved by improving the efficiency of equipment and personnel, as well as production processes. Asahi Tekko, a Toyota-affiliated supplier, has succeeded in significantly increasing efficiency by utilizing IOT (Internet Of Things, mainly by attaching sensors to production equipment and exchanging and controlling information via the Internet) in order to improve productivity (reference). - Establishment of a sustainable supply chain model

A long-term stable supply system can be established by planning a Business Continuity Plan (BCP), as described below, and by adopting materials with low environmental impact (easy to recycle, durable, etc.) and manufacturing processes (reduced use of water and energy, reduced CO2 emissions by devising transportation methods, etc.).

In the digital age, you can also consider sharing data about procurement. The focus will also be on how to share and leverage digital data between sellers and buyers. There are sensitivities in terms of data security and privacy, and it is important to define well in advance what is needed and design a procurement infrastructure that also works with accounting, finance, and sales. I would like to share my past mistakes in sometime later.

- Procurement Data (all information related to procurement activities)

Data is the foundation of digital transformation. In the supply chain, the sharing of procurement data such as purchasing prices, production plans, order quantities, delivery dates, inventory counts, etc., enhances collaboration between sellers and buyers and creates new value. For example, the more a seller knows in advance what, how many, when, and where a buyer will order, the more time seller has to prepare for production and ensure a stable supply. For example, Toyota Motor Corporation shares and coordinates data with its suppliers on a frequent basis, including production planning at the planning stage, annual, semiannual, and monthly basis when mass production starts, and finally, daily orders by kanban. - IT Infrastructure for Procurement

The management of purchase price, quantity, and inventory quantity is not possible without IT infrastructure. By sharing the IT infrastructure for procurement (known as ERP or BSM) with seller, buyer can automate the ordering and delivery process and manage delivery record with software. Currently, cloud services provided by external service providers are becoming popular. The reason for their popularity is that cloud services are easy to design and maintain and can be used across countries. However, when implementing cloud services, operations must be adapted to the cloud service. For this reason, some large companies develop their own procurement IT infrastructure or modify the cloud service in order not to change their own operations. In addition, the reality is sellers need to be familiar with the procurement IT infrastructure of various buyers. - Externally Provided Services

Externally provided services are services or functions that a company cannot / does not develop by its own, but instead an outside company develops. Externally provided services are effective for functions that require specialized knowledge and technology, and for those that need to be implemented and operated in a short period of time. Examples include IT infrastructure selection and operational design for procurement (e.g., how data is shared between the seller and buyer) by an objective third-party consultant who is not an IT infrastructure agency / distributor. - Transforming Procurement Operations

Conventional procurement processes involve paper-based interactions and subjective, often not standardized work, making operational efficiency and productivity improvement a challenge. Digitalization makes it possible to evaluate suppliers objectively and identify issues based on quantitative data in procurement operations. At the same time, suppliers can share data and issues to strengthen the cooperative relationship between seller and buyer. The procurement department is an important department that contributes significantly to corporate productivity and competitiveness through the procurement of goods and services. Digital transformation can strengthen the procurement function. - Data security and digital privacy

seller and buyer must be careful for the shared data leakage. Procurement, in particular, handles valuable data of both itself (buyer) and its supplier (seller), so it is necessary to take measures to ensure data security and privacy.

A flexible supply chain in emergency situations means that a company is prepared to provide continuous production and services in the event of a disaster or emergency. Especially recently, procurement has been facing various challenges such as pandemics, wars, and natural disasters. The focus on stable supply has been increasing more than ever. We have posted a blog on disasters before. We introduce some methods to increase supply sources and enable quick response by switching from Self Sourced materials procured or manufactured by seller to Custom Supplied materials by buyer.

There are three elements to consider when developing a flexible supply chain strategy for emergency situations. Because of the enormous amount of work involved in trying to do this, it is a good idea to prioritize materials.

- Risk Management

It is a good idea to start with clarifying what risks exist in the supply chain. In Japan, after the Great East Japan Earthquake in 2011, companies have been developing BCPs (Business Continuity Plans) mainly for natural disasters such as earthquakes and typhoons. But what about overseas? Various risks are possible, including man-made disasters such as terrorism and war, and changes in social conditions such as labor disputes and political turmoil. - Advance Planning

Next, buyer plans in advance how to respond in the event of an emergency. There are countermeasures such as multiple manufacturing sites and alternative materials. One of the countermeasures here is an option to switch from Self Sourced materials to Customer Supplied materials. Commercial agreement and technical verification between seller and buyer are required in advance. Furthermore, planning for the stock quantity of supplied materials and securing alternative production sites will enable a quick and effective response in case of an emergency. - Continuous Improvement

The business environment is constantly changing. It is important to regularly review and improve your emergency supply chain as well. By identifying new risks and considering countermeasures to address them, an optimal backup system can be maintained at all times.

Successful examples include the following.

- Toyota Motor Corporation

Toyota has been working with all suppliers to visualize and systematize its supply chain to respond more quickly in case of emergency (reference). - Amazon AWS (Cloud Computing Service)

Amazon has distributed servers (computing power sources) across multiple regions, and buildings are designed to comply with Japanese earthquake standards, ensuring backup and restoration of data and power to support rapid recovery in the event of a disaster (reference).

I have previous experience providing customer supplies out of necessity. I would like to share some of the risks and take backs.

An electrical component that had been procured were claimed to be waterproof, but in fact they were not. In addition, there were also problems caused by static electricity (this was an unforeseen problem and not covered under warranty). The supplier was not capable of designing a waterproof case and had to supply metal parts that were designed to be waterproof.

In cooperation with a mechanical engineer, a waterproof enclosure was designed, tested (waterproof, dustproof, electromagnetic radiation, etc.), and installed. The waterproof case was Customer Supplied after deducting the original case cost from the electrical component. We were also able to alleviate the problem of static electricity by using other components.

We were able to secure Waterproof performance and resolve the initial key issue. Regarding static electricity, there would be a risk of the ambiguous liability (it would be difficult to determine whether the lack of countermeasures was due to the case or the circuit board inside). As takebacks, it is important to identify risks of Customer Supply and to verify if the risks are manageable.

Enserve can help you to Customer Supply for special steel, stainless steel, and copper alloys from different angles.

| Angle | Enserve Proposal |

|---|---|

| Cost | |

| Quality | |

| Stable Supply | |

| Digital | |

| BCP |