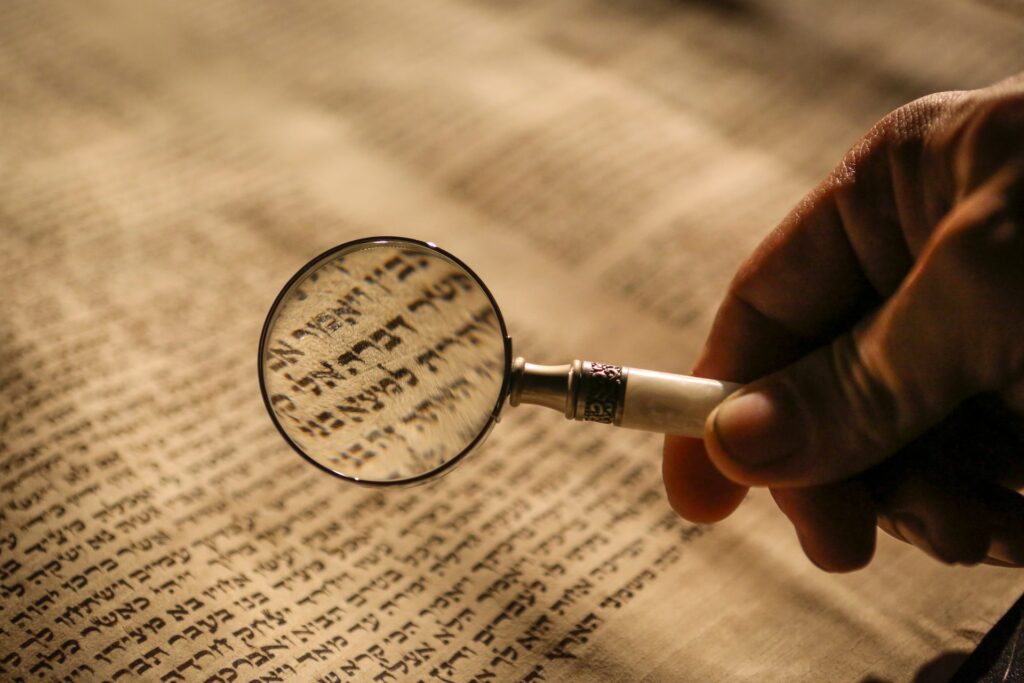

Special steels are steels that have specific properties and performance characteristics compared to ordinary steels (alloys of iron and carbon). They are manufactured using specific alloying element additions, heat treatments, or fabrication techniques to meet special applications or requirements. This allows special steels to have different strength, wear resistance, corrosion resistance, heat resistance, electrical conductivity, and other properties to suit different applications. Stainless steel is one type of special steel.

Since its inception, Enserve has been dealing with special steels and stainless steels that are hard to obtain in your area. Enserve is a unique source of consultation in various industries based on the following four advantages.

Among special steels, there are some rare grades that require high hardness etc. and the volume for steel mill is low. In these cases, the delivery LT tends to be longer than the your requirements, or stable supply of these rare steel grades might be questionable in the future. Enserve specializes in proposing alternative materials for such rare steel grades from all over the world, including niche overseas special steels and stainless steels that are JIS certified and have been delivered to Japanese manufacturers. Our customers often consult us to arrange substitutes for rare special steels that are too niche and difficult to find elsewhere.

The quality and cost levels required for metal materials vary depending on the application, even for the same steel grade. Enserve offers a wide range of mother materials from the world’s best quality to the most cost-competitive, depending on the your application. This sense of balance is one of our strengths as a company with a background in manufacturing.

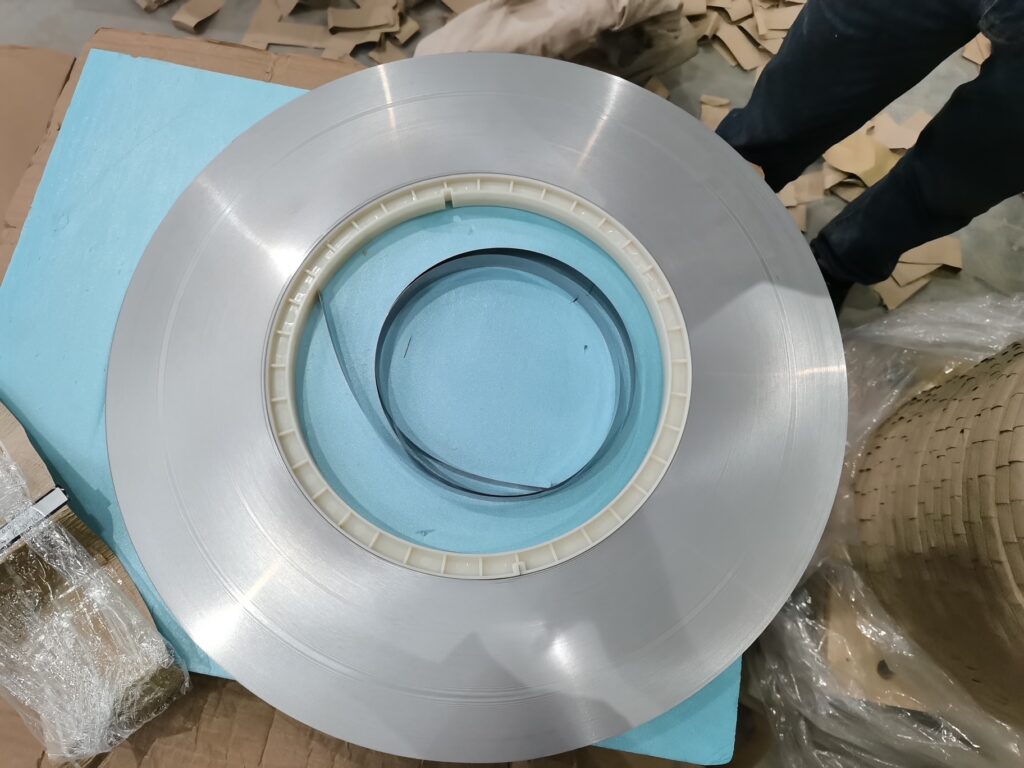

Enserve is able to quickly establish a flexible supply chain from mother materials to processing across countries. You can use the delivered products as soon as you receive them. For example, steel mills can only process coils up to 1.5 mm thickness, and there are sometimes differences in surface finish between the your requirements and steel mills. We can arrange further rolling, surface finishing, metal fabrications (stamping, welding etc.), third party inspection, and JIT delivery system.

Enserve has a manufacturing background. We have a deep understanding of not only special steel and stainless steel materials, but also the development process and operating environments especially in the automotive, industrial machinery, medical, and marine petroleum industries. We care that you are happy to use our products. If there is any issue, we communicate sincerely and fairly with you and manufacturing partners to resolve the issue.

We offer special steels and stainless steels that offer advantages to you in terms of rarity, quality, price, and delivery time. If you have a problem that cannot be solved with an existing steel grade or a steel grade that is not on the list, please contact us. There are steel mills in the world that produce steel grades that are not available in your area, so we may be able to make a proposal that can solve your problem.

| JIS | ASTM | BS | DIN | NF | ISO |

|---|---|---|---|---|---|

| SK65 (SK7) | W1-7 1065 | 060A67 060A72 | C70W2 (1.1620) | C70E2U | TC70 |

| SK75 (SK6) | W1-8 1075 | 060A81 | C85W (1.1830) | X75 | TC80 |

| SK85 (SK5) | W1-8 1085 | 060A78 060A81 | C80W1 | C80E2U | TC80 |

| SK95 (SK4) | W1-9 1095 | – | – | C105E2U | TC105 |

| SK105 (SK3) | W1-10 | 1,407 | 105CR2 (1.3501) | C105E2U | TC105 |

| SK120 (SK2) | W1-11 | 1,407 | 125CR2 (1.2002) | C120E3U | TC120 |

| SK140 (SK1) | – | – | C130W2 | C140E3U | TC140 |

| S45C | 1045 | C45E (C45R) | C45 | C45 | C45E4 (C45N2) |

| SCM415 | 15CrMo4 | 15CrMo4 (1.7243) | 15CrMo4 | 15CrMo4 | |

| SCM435 | 4137 | 34CrMo4 | 34CrMo4 (1.7220) | 34CrMo4 | 34CrMo4 |

| SUS304 | 304 | X5CrNi18-10 | X5CrNi18-10 (1.4301) | X5CrNi18-10 | X5CrNi18-10 |

| SUS316 | 316 | X5CrNiMo17-12-2 | X5CrNiMo17-12-2 (1.4401) | X5CrNiMo17-12-2 | X5CrNiMo17-12-2 |

| SUS430 | 430 | 430S17 430S18 | X6Cr17 (1.4016) | Z8C17 | X6Cr17 |

| SUS430LX | 439 (430Ti) | 00Cr17 (022Cr18Ti) | X3CrTi17 (1.4510) | X3CrTi17 | |

| SUS443CT (upgraded 304) | 304 | 304S15 (304S31) | X5CrNi18-10 (1.4301) | X5CrNi18-10 | X5CrNi18-10 |

| – | – | – | X68Cr13 (1.4037) | X68Cr13 | X68Cr13 |

| – | – | – | X65Cr13 (1.4037) | X65Cr13 | X65Cr13 |

| SUS420J2 | 420 | X30Cr13 (1.4028) | X30Cr13 | X30Cr13 | |

| CB5 | – | – | – | – | – |

| CB6 | – | – | – | – | – |

| SUS440A | 440A | 7Cr17 | X68Cr17 (1.4109) | X68Cr17 | X68Cr17 |

| SUS440B | 440B | – | X90CrMov18 (1.4112) | – | – |

| SUH446 | 446 | X18CrN28 (1.4749) | X18CrN28 | X18CrN28 | |

| – | – | – | X39CrMo17 (1.4122) | X39CrMo17 | X39CrMo17 |

We offer various steel shapes in coil, strip, bar (from cast billet material fresh out of the furnace to cold drawn bar), and wire (round, flat, and deformed). If you have a special shape that is not listed, or if you have tight dimensions or tolerances that are difficult to establish an optimal supply chain, we can help. Enserve can propose the optimum supply chain by utilizing our worldwide network of manufacturing partners.

| Category | Strip | Coil | Bar | Wire |

|---|---|---|---|---|

| Description | Cold Roll & Quenching Tempering | Cold Roll | Round, Flat, Hexagon | Round, Flat, Deformed |

| Thickness (T) | 0.02~1.30mm | 0.25~1.50mm | 2.0~500.0mm | 0.0025~30.0mm |

| Tolerance on T | ±10% of T~ | ±0.012mm~ | TBA | TBA |

| Width (W) | 8.0~1000.0mm | 1000mm~1250mm | – | – |

| Tolerance on W | ±0.04mm~ | ±0.04mm~ | ±0.20mm~ | – |

| Finish | Bright,Semi Bright, Dull | BA, 2D, No.4, Hair Line, Embossed | Bright, Non Bright | Bright, Semi Bright, Dull |

Applications of special steel and stainless are listed as below. For other applications, we are open for discussion.

| Strip | Coil | Bar | Wire |

|---|---|---|---|

| Blade, Saw, Cutter | Washing Machine | Gear | Rail for Train Door |

| Cutlery, Knife, Razor | Dish Washer | Shaft | Ice Cream Stirring Bar |

| Staple | Kitchen Sink | Cold Headers | Towel Rack |

| Knitting Machine Needle | Toaster | Bolts, Pins | Cup Handle |

| Thrust Washer | Kettle | Forgings | Peeler Handle |

| Clutch Valve Bracket | Expresso Machine | Engine Components | Nozzle |

| Horn Diaphragm | Refrigerator | Wheel | Nut for Precision Machines |

| Bearing Drive Wheel Cap | Garbage Can | Machine Components | |

| Tape Measure | BBQ Grill | Wedge Wire | |

| Spacer in Rocker Arm | Range Food | Watch Band | |

| Feeler Gauge | Hard Disc | Conveyer Belt | |

| Washer, Wave Washer | Kitchen Stove | Medical Device | |

| Hose Band | Grating (Ditch Lid) | ||

| Gasket | Printer Shaft | ||

| Spatula, Trowel | Auto Door Rail | ||

| Rotary Compressor Parts | Rack Gear | ||

| Slap Bracelet | |||

| Anti-loosening of Screws |

We offer Welding Consumables that are difficult to find. For further details please check here.

Upon hearing your needs, Enserve offers best QCD for special steel and stainless in the grade, shape, size, and additional processing you require. Also applying our metal x manufacturing knowhow, we offer Japanese quality medical steel products. Please feel free to contact us if you have any issues about special steel and stainless steel.