Switching Supply Chain smoothly like switching trains (without delay or mistakes)

Switching Supply Chain is like switching trains. It requires smooth transition to avoid delay or confusion. This case study demonstrates how Enserve contributes customer’s business sustainability by switching its supply chain.

A mechanical engineering company uses a rare special steel billet for its special processing. However, due to the steel grade discontinuation, Enserve had a consultation to arrange alternative a supply chain for the customer’s business sustainability.

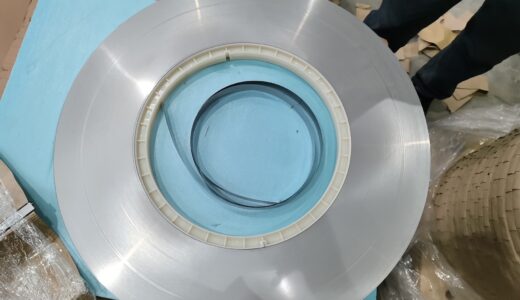

Recently, steel mills in Japan often review their product portofolio for more volume, more profit, and more cutting edge applications. This customer had used a rare special grade for long time, but it finally faced the risk of not being able to procure the steel grade. What’s more, the customer uses the steel in billet form (reference), which is the raw material of steel. There were two probelms.

- Steel Grade was difficult to find

- A relatively small quantity of billet did not meet steel mills MOQs (Minimum Order Quantities)

We had three key points to resolve the problem.

- Enseve referred steel mill list all over the world which produces special steels

- Enserve managed to find a steel mill which regularly produce the special steel in billet form

- Enserve further arranged a partner ironworks to cut the large billet into the required sizes

Because steel grade was rare and volume was suitable for electrical furnace mill, Enserve checked electrical furnace mills products one by one. Most of them showed the steel grade in their catalogue but actually did not produce them. Or even if some of them produce, they do not produce in required shape. Enserve was finally able to find one steel mill which produces the required steel grade in the required form. However, the steel mill produces the billet whose length was longer than the customer’s requirement. The steel mill did not own sawing machine either.

Enserve searched further which owns sawing machine for billet. Most of local distributors owned sawing machines but these sawing machines were for round bars (much smaller diameters than billets). There were language problem as well. Enserve in the end was able to find potential partners to cut the billets from local ironworks and made agreement with the steel mill that mill will cooperate to arrange the cutting process.

The sample is to be evaluated. If the evaluation result is good, the customer can continue delivering its product. This case study demonstrates that Enserve was able to establish supply chains independently and flexibly for each process appropriate for each inquiry. Enserve does contribute to establish alternative supply chain for customer’s business sustainability. We believe our role is like a guide for travelers (customers) to switch trains smoothly to arrive the travelers’ destination on time.