We specialize in sourcing hard-to-find special steels, stainless steels, and copper alloys. With our global network, we excel at locating materials with precise specifications, including grade, shape, dimension, and surface finish. By providing comprehensive support from material discovery to sample evaluation and factory audits, we empower you to focus on their core business such as product development while we handle the complexities of global metal sourcing.

To source special steels or copper alloys, why availability is sometimes a challenge? There are 3 main reasons.

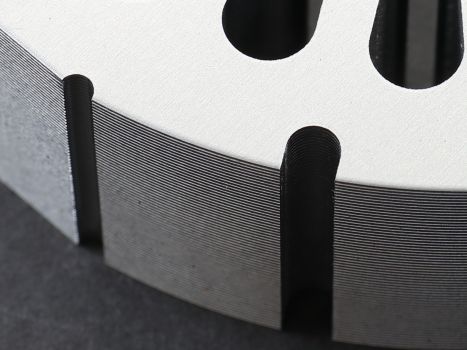

Finding a perfect match for niche metals can be challenging due to varying specifications. Steel mills may produce grades not listed in their product catalogs or vice versa. Additionally, factors such as shape, dimensions, surface treatment, and geometric tolerances can complicate the sourcing process. Some manufacturers may require minimum order quantities (MOQs) that are too large for specific projects, or lack the necessary equipment to meet custom requirements.

Even when materials meet the specified grade and dimensions, quality can still be a concern, especially for mass production-scale applications. Manufacturing processes can vary between prototypes and mass production, leading to potential quality inconsistencies. Furthermore, while materials from reputable steel mills may meet certain standards, performance guarantees after further processing (e.g., heat treatment) are often not provided.

Cost is always a significant factor in the procurement process. While cost priorities vary across industries and cultures, you always have a certain expectation on quality level. Quality can be defined by tangible factors such as dimensions and tolerances, or more subjective factors such as surface finish and grinding smoothness. Balancing cost and quality is often a complex challenge.

Delivery Lead Time is crucial, both during the evaluation phase and when scaling up for mass production. While large corporations may provide conservative delivery estimates, smaller manufacturers might experience unexpected delays. It’s essential to assess the potential risks to the supply chain disruptions and delivery delays.

Through years of collaboration with our clients, Enserve has honed its ability to source even the most elusive niche metals.

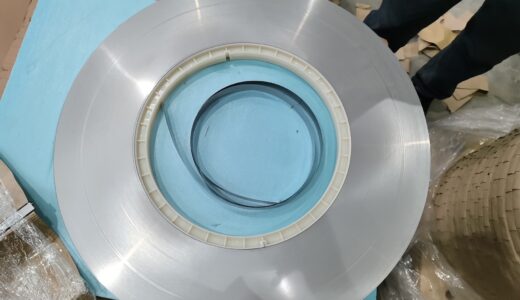

Special steels and copper alloys have evolved uniquely in different countries to meet specific needs, resulting in a wide range of grades (chemical compositions, physical properties, mechanical properties, and processing characteristics), shape, size, surface appearances. With years of experience in sourcing these materials, we have developed a deep understanding of the capabilities and limitations of manufacturers worldwide. We can often find the perfect match for your requirements, or suggest alternative materials or processes to meet your needs. Additionally, we offer flexible purchasing options, such as consolidating orders to meet minimum quantity requirements.

We work closely with you to develop a phased approach to material evaluation and adoption to your business / production. This involves gradually increasing quantities to assess quality consistency in a production environment. We also explore automation options to ensure that desired quality levels are consistently met.

Cost is a critical factor in any procurement decision. By clearly defining quality requirements, including appearance, we can provide accurate cost estimates. Our focus is respect on both clients and suppliers and make proposals to benefit both clients and suppliers such as revising appearance criteria, automation of certain processes, adopting different process methods etc.

Timely delivery is essential. We carefully evaluate lead times of a raw material and processes to identify and mitigate risks that could impact delivery schedules. In addition to direct delivery from the manufactures, we offer flexible options such as stock programs and partial shipments to ensure that your project stays on track.

What could take you hundreds of hours, we can often accomplish in just a few. If you’re spending valuable time searching for materials, let us handle it so you can focus on product development.