Do you need to procure new metal material or components or build a new supply chain? Or are you considering changing some of your current metal material / component suppliers? Isn’t it overwhelming for complex sourcing, regulations, and logistics. Enserve is your one-stop shop for developing a custom metal supply chain solution that meets your exact needs.

There are 4 challenges for developing new metal material / component supply chains.

Reliability, not only the product quality but also communication is the key element of developing new suppliers.

Even if it is implicit with current suppliers, criteria and expectations must be communicated and met with new suppliers regarding QCD (quality, cost, and delivery).

Import regulations, tariffs, and legal requirements must be clarified. Oversea trade requires financial risks that limits your cash flow.

Coordinating logistics and pre-processing for in-house use are operational preparation for actual installation.

By working with Enserve, you can reduce the risk of failure for new supply chain development. Then you can focus on other important issues.

We identify and qualify the best suppliers for your specific needs. Depending on your priority, we prioritize the combinations of our manufacturing partners. You can save much time and resources to focus on other, often tasks.

We first help listening to or even bouncing ideas off the wall to clarify your criteria and hidden needs for QCD. Based on your QCD expectations, we offer supply chain proposals to satisfy your quality, cost, delivery expectations. To ensure quality, we often arrange a third party inspection as well. You can leave us everything from initial sourcing to commercial deliveries.

We handle all legal aspects such as import regulations and tariffs to ensure smooth and compliant deliveries. We also explore trade finance options to streamline your cash flow.

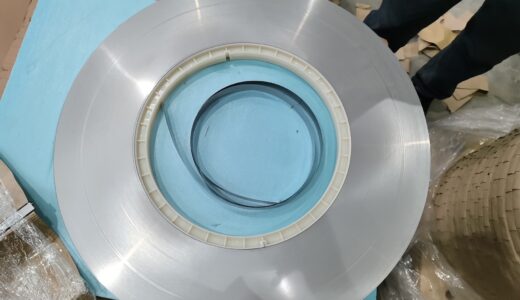

We Enserve have more than 50 years of operational preparation such as pre-processing and packing to ensure peace in mind deliveries.

Enserve is a professional vendor in Tokyo specialized in Metals (Special Steel, Stainless, Copper Alloy) x Manufacturing (Industrial, Medical, Marine Petroleum). We establish tailor-made Supply Chain from all over the world to find your procurement solutions in the following areas.

We have a case study how we carefully assist our customer for stable supply chain without sacrificing quality.