Surging material cost / Inflation is a headache for all manufacturing businesses. We have frequently witnessed an attempt to reduce costs to be frustrated by unexpected quality pitfalls.

We Enserve strive to understand our customers’ quality expectations and respond quickly to inflation while maintaining quality.

There are 3 challenges for metal material / component in terms of inflation.

One characteristics of metal supply chain is that the raw material manufacturer is very powerful compared to its customers (distributors, intermediate processors and end users). If the raw material manufacturer decides to increase the price, customers often cannot refuse but to accept.

The historical data indicate that prices are sticky and inflation can last for long time (reference). This sticky inflation may lead long term increase in raw material / component prices.

Changing raw material / component itself is also challenge due to quality concerns. The replacement process of raw materials / component takes long time to evaluate if an alternative raw material / component is acceptable in terms of quality performance. Besides, there might be unexpected quality issues of changing raw material / component. Rather than getting exposed to these risks, you may stand up with the current material / component.

By working with Enserve, you can reduce the risk of failure to address surging material costs and inflation, improve your profitability, and ensure the long-term success of your manufacturing business.

Enserve can help you identify areas where you can reduce costs without sacrificing quality. Especially, for those metal materials or components that you suffer for a single source, we will do our best to propose alternatives.

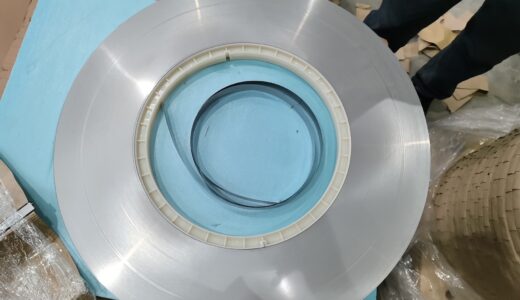

Enserve also has expertise for value added metal materials / components (especially in medical wire / wire components, cut or grind function related materials). We assist you to increase the value of your product to increase your price and sales.

We understand the importance of maintaining your quality standards while also improving your bottom line. Our cost-reduction plans will take this into account, ensuring that you can stay competitive without compromising on the quality of your products.

Enserve doesn’t offer a one-size-fits-all approach or a standard product. We will work with you to understand your specific challenges and develop a tailored plan that meets your unique needs and budget.

Enserve is a professional vendor in Tokyo specialized in Metals (Special Steel, Stainless, Copper Alloy) x Manufacturing (Industrial, Medical, Marine Petroleum). We establish tailor-made Supply Chain from all over the world to find your procurement solutions in the following areas.

We have a case study how we carefully assist our customer for an alternative supply chain without sacrificing quality.